Comprehensive Guide to Concrete Scanning Technologies

Comprehensive Guide to Concrete Scanning Technologies

Blog Article

Unveil the Transformative Power of Concrete Scanning in Maximizing Efficiency and Safety And Security

Concrete scanning has become an important device in the construction market, using unparalleled advantages in enhancing project efficiency and making certain safety standards. By making use of advanced technology, concrete scanning enables experts to see beyond the surface area, discovering concealed intricacies that can affect the structural honesty of a structure. The transformative power of concrete scanning lies in its capability to supply thorough insights and real-time data, transforming just how jobs are prepared and implemented. As we dig right into the details of this ingenious method, a globe of opportunities opens up, showcasing a brand-new era of construction practices that prioritize precision and safety and security.

Importance of Concrete Scanning

Ensuring the architectural integrity and safety and security of building and construction jobs begins with the essential action of carrying out extensive concrete scanning. Concrete scanning is a non-destructive method used to discover and map subsurface elements within concrete structures.

Additionally, concrete scanning helps in optimizing task timelines and budget plan by preventing unforeseen expenses and delays that may emerge due to unforeseen obstructions within the concrete. Inevitably, investing in comprehensive concrete scanning is a positive method that improves both performance and safety and security in building jobs.

Exactly How Concrete Scanning Works

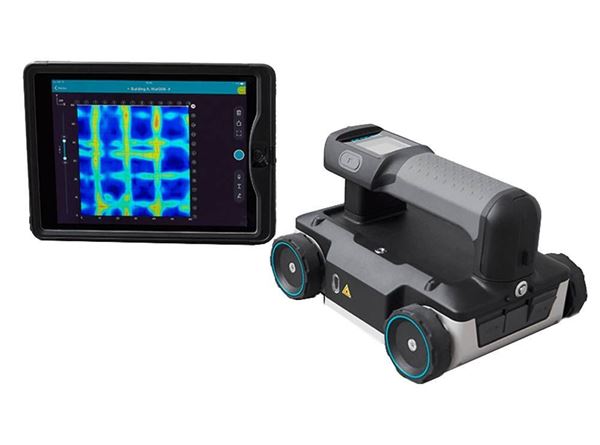

Concrete scanning operates as a crucial device in construction projects by employing innovative modern technologies to detect and map subsurface aspects without triggering architectural damage. Ground Permeating Radar (GPR) and Electromagnetic Induction (EMI) are two main techniques utilized in concrete scanning. GPR works by giving off high-frequency radar pulses into the surface area, which get better when they come across subsurface things or gaps. The moment considered the signal to return suggests the depth and place of the things. EMI, on the other hand, uses electro-magnetic fields to identify variances in product compositions, such as determining rebar or conduits within concrete structures.

During the scanning process, the information gathered is evaluated in real-time, enabling immediate recognition of possible threats or obstacles beneath the surface. By using these sophisticated modern technologies, concrete scanning dramatically decreases the threat of expensive damages and injuries on construction websites.

Benefits of Concrete Scanning

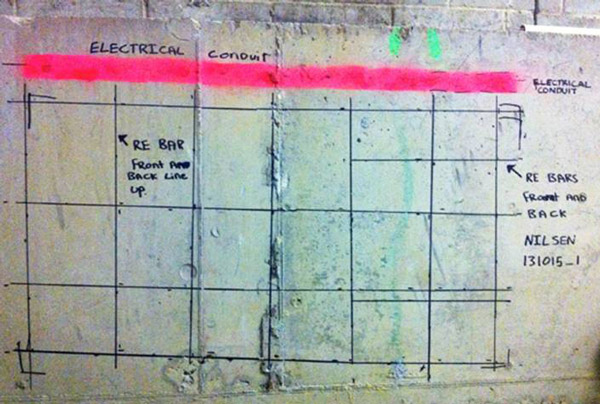

One of the main advantages of concrete scanning is the ability to spot and find ingrained items such as rebar, post-tension wires, and avenues accurately. Concrete scanning assists in planning and designing much more properly, as it offers exact info concerning the place and depth of architectural elements.

Study: Concrete Scanning Success

In another case, a building and construction company used 3D concrete scanning to analyze the problem of maturing concrete structures in a historic building. The detailed scans provided useful understandings into the extent of degeneration and aided focus on maintenance initiatives successfully. By proactively attending to locations of concern recognized through scanning, the company was able to extend the lifespan of the framework and guarantee resident security.

These study highlight the transformative power of concrete scanning in enhancing performance, accuracy, and safety in building and construction jobs.

Applying Concrete Scanning in Projects

Carrying out sophisticated scanning innovations throughout building and construction tasks has actually become increasingly necessary for enhancing accuracy and security. By integrating concrete scanning into project preparation and execution, construction teams can identify prospective threats, such as rebar or post-tension cable televisions, hidden within concrete structures. This proactive technique lessens the risk of mishaps, delays, and expensive rework, ultimately resulting in more effective job timelines and budget plans.

To implement concrete scanning successfully, job supervisors ought to collaborate closely with knowledgeable scanning experts to figure out the most ideal scanning strategies for the details task demands. Involving scanning specialists from the early stages of a project makes it possible for the team to produce detailed scanning plans that attend to vital areas of issue and ensure extensive information collection.

In addition, including concrete scanning right into regular project operations can simplify decision-making procedures, as real-time scan information gives immediate understandings right into the condition of concrete frameworks - Concrete Scanning. This data-driven method facilitates notified analytical and allows groups to make adjustments immediately, promoting a culture of performance and safety and security throughout the task lifecycle

Final Thought

In final thought, concrete scanning plays an essential role in boosting effectiveness and security in construction jobs. her response By making use of sophisticated technology to map and find out underlying frameworks within concrete, this process helps to protect against pricey blunders, ensure structural stability, and decrease threats on site. With the capability to uncover covert aspects and offer accurate data, concrete scanning proves to be a useful tool for enhancing job outcomes and maximizing total success.

Concrete scanning is a non-destructive technique used to identify and map subsurface aspects within concrete frameworks. Additionally, concrete scanning aids in enhancing task timelines and spending plan by avoiding unexpected expenses and delays that may occur due to unpredicted obstructions within the concrete. One noteworthy situation research study involves a large-scale restoration job where concrete scanning played a vital role in guaranteeing project success.In one more instance, a building and construction company used 3D concrete scanning to analyze the condition of maturing concrete structures in a historic structure. By incorporating concrete scanning into project preparation and execution, building groups can recognize potential threats, such as rebar or post-tension cable televisions, concealed within concrete structures.

Report this page